Flexure Design for Muscle Tissue Measurement

Design of a compliant precision sensing device to measure the displacement and output force of engineered muscle tissue contractions.

Motivation

- Muscle tissue diseases affect millions, but current drug evaluation methods do not directly measure mechanical function, expose participants to risk, take years, and can cost millions of dollars.

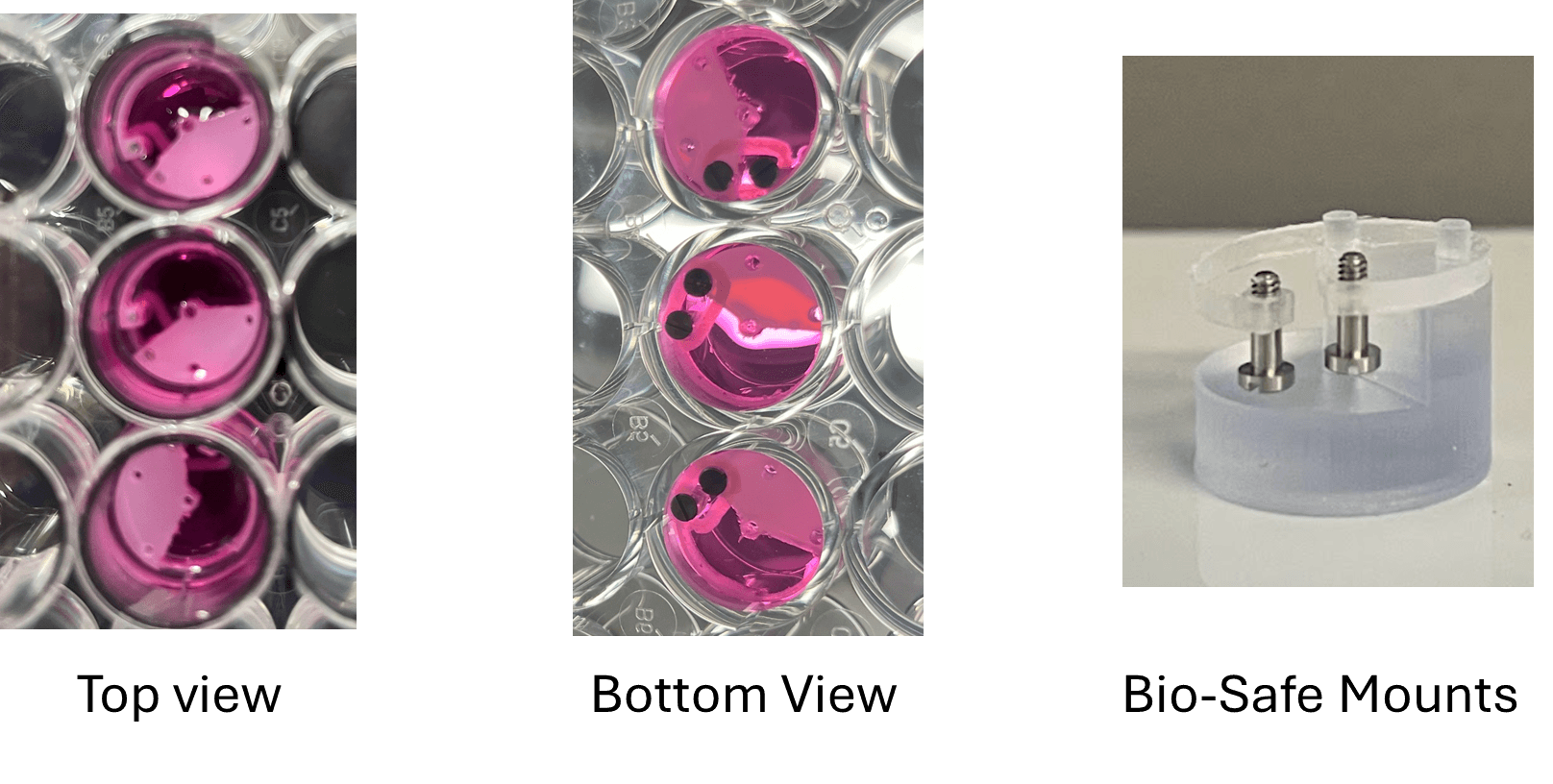

- hiPSC - derived muscle tissue has been developed. These tissues mimic native muscle and can fit inside a 24-well plate, enabling high-throughput testing.

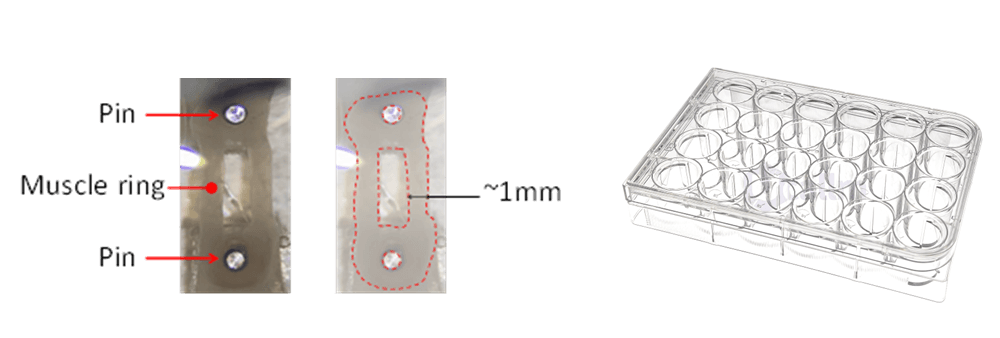

muscle rings and 24-well plate

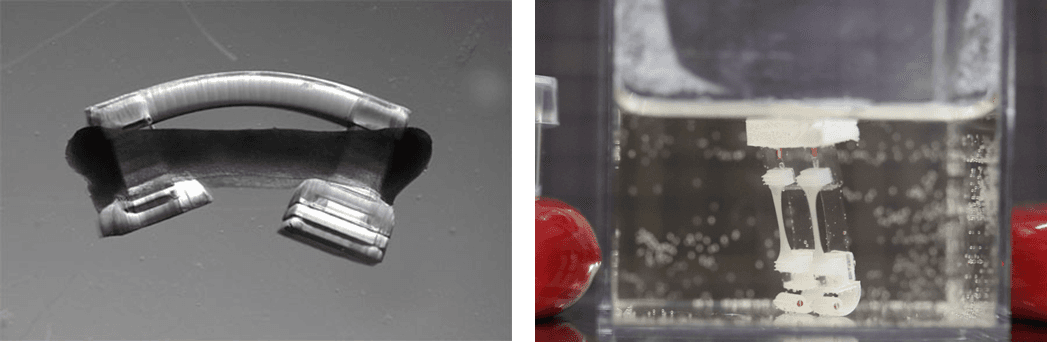

Research is also being done to explore the use of these muscles in biohybrid robots.

Biohybrid robots

This has motivated the development of a precision measurement device to characterize the force output of these muscles.

Device Requirements

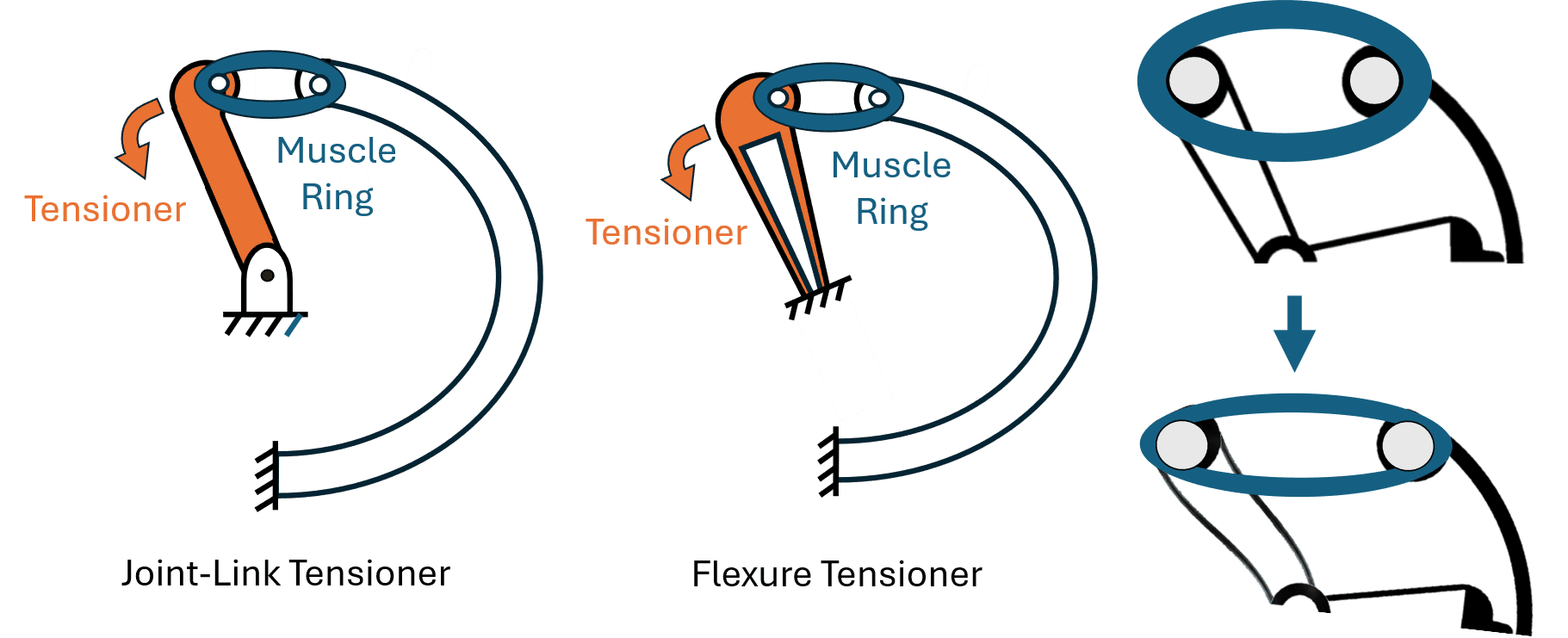

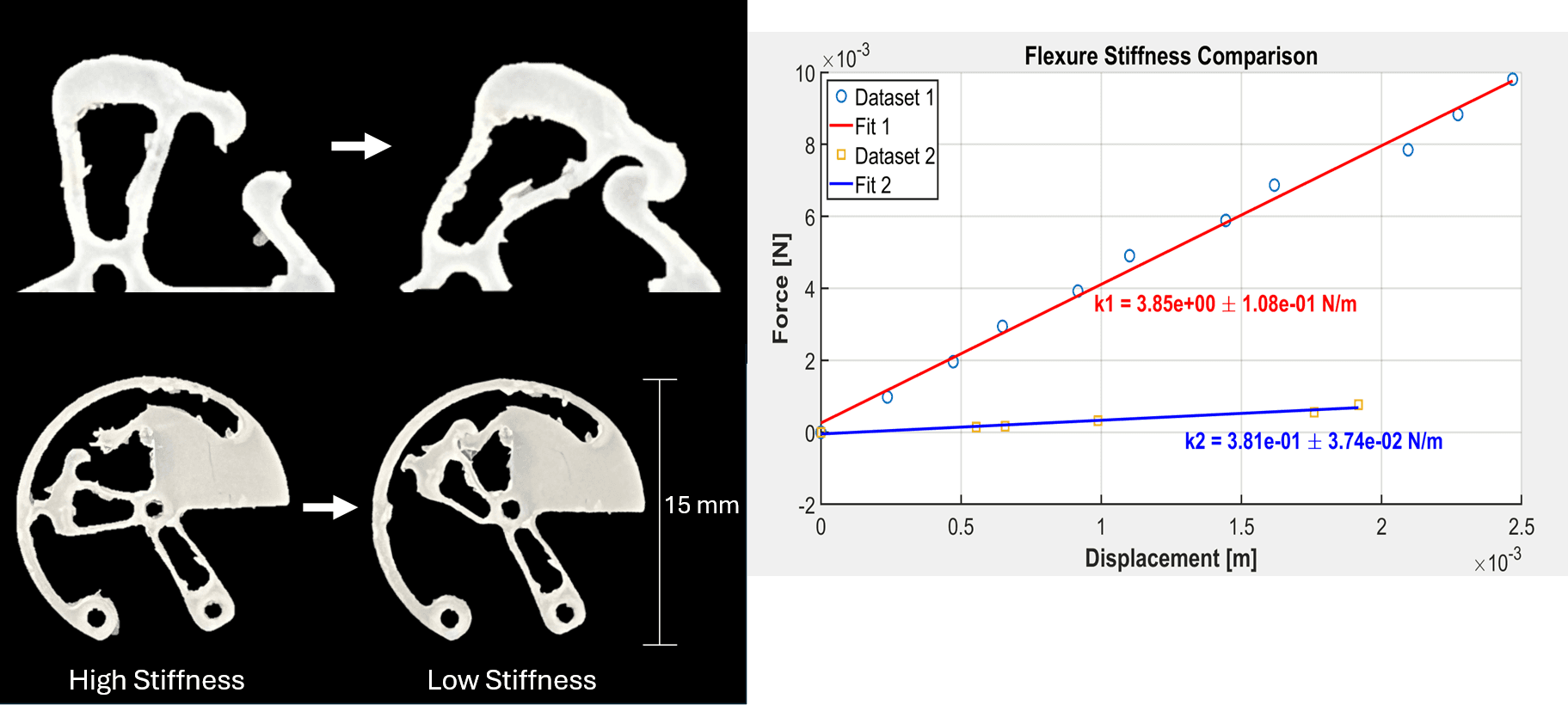

- Variable stiffness (0.3-3 N/m) allows the muscle to both grow on the device and show contraction without moving the muscle from one device to another.

- Muscle tension reduces slack & accounts for variable geometry

- Fits inside 24 well plate

- Mass-manufacturable (10s of thousands annual)

- Cost <10s of USD per unit

Design Methods

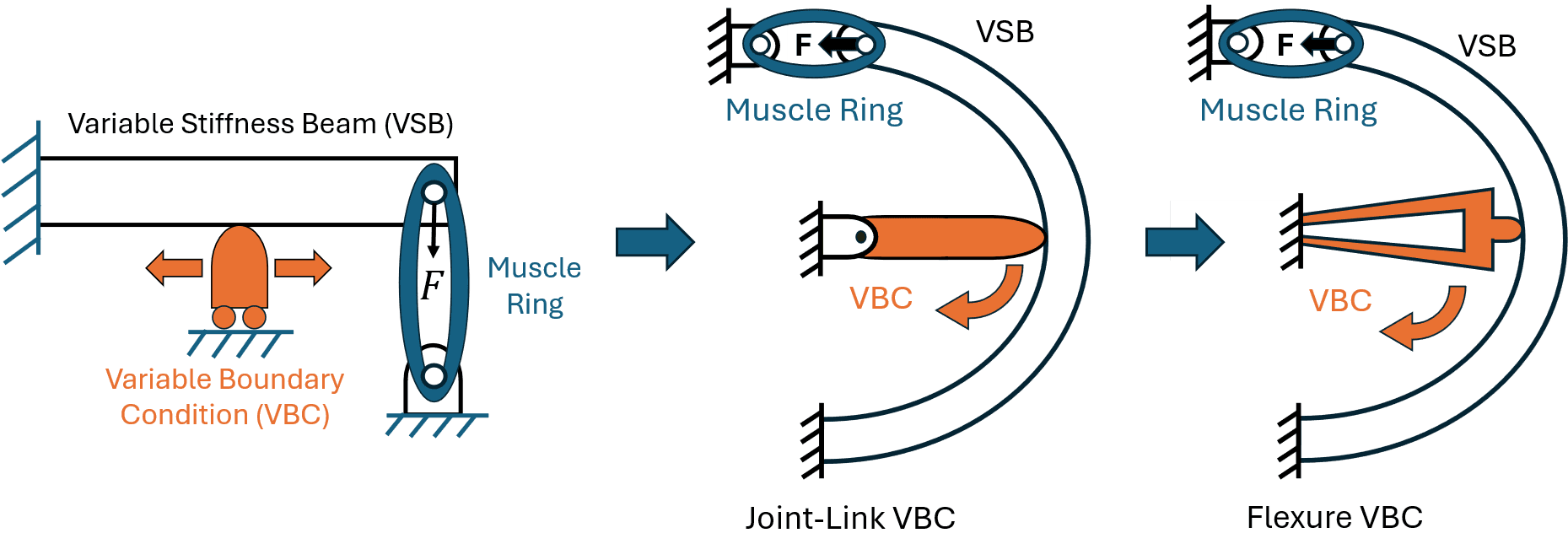

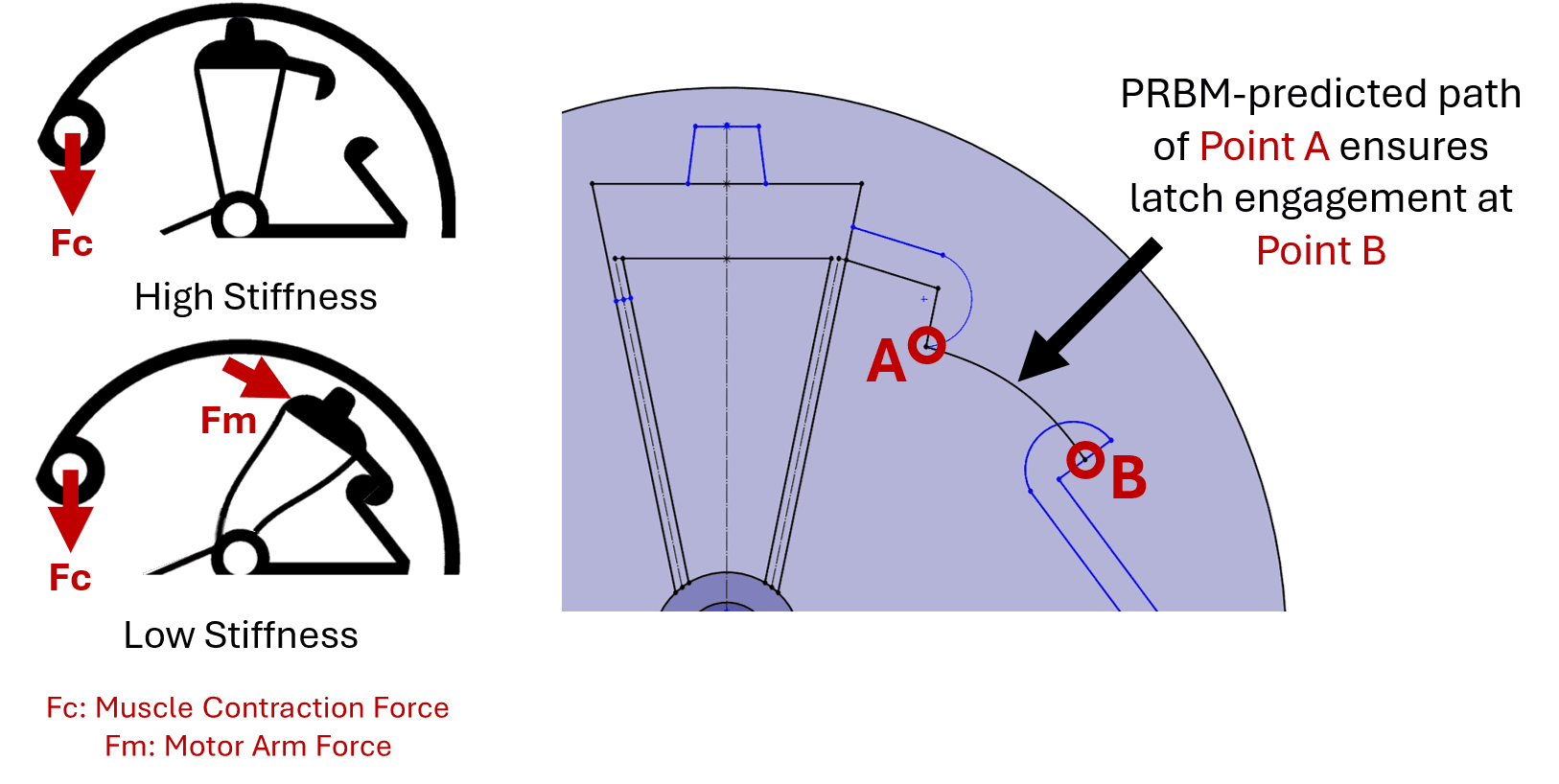

Evolution of variable boundary condition design

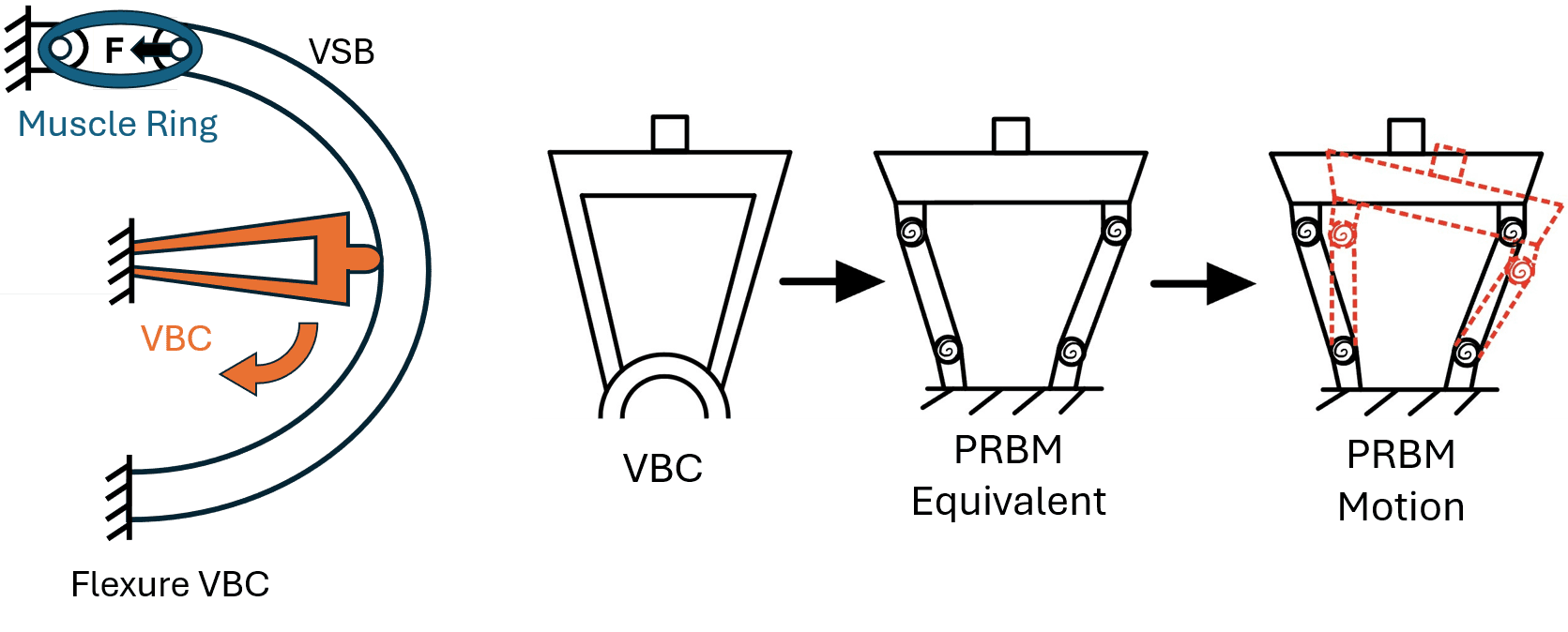

Pseudo-rigid-body modeling methods to track boundary condition

PRBM-defined path trajectory following

Latching PRBM-defined variable boundary condition

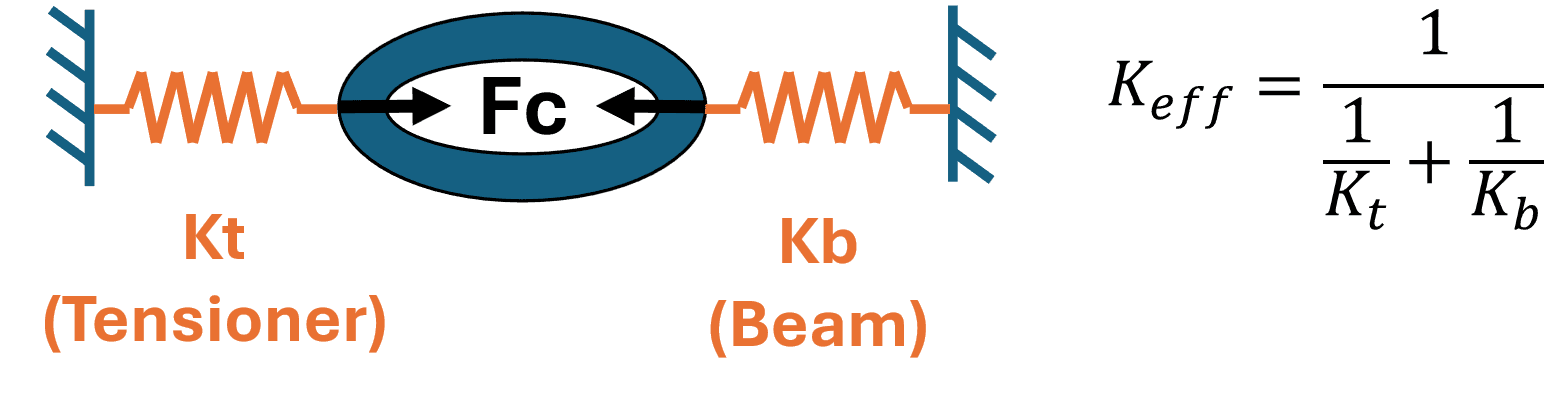

Tensioner design

Tensioner and VSB are springs in series

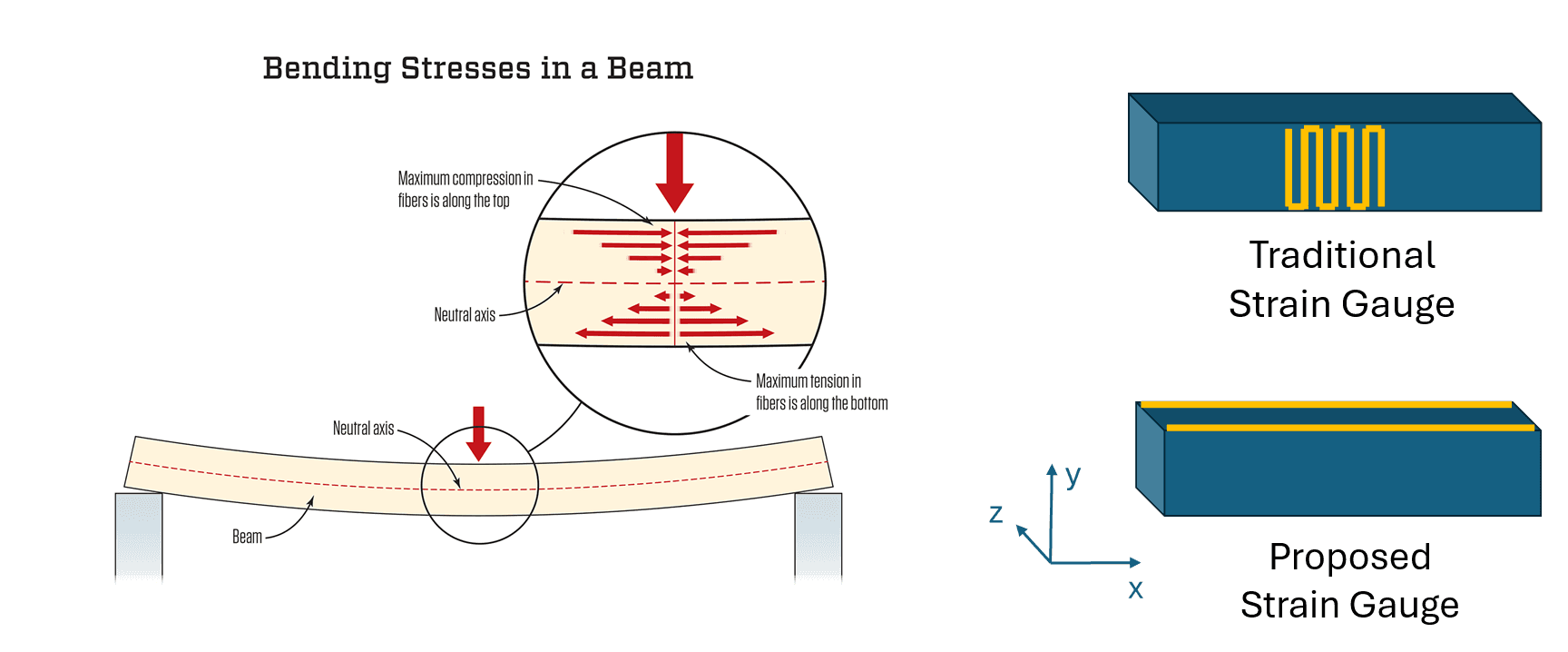

Measurement Methods

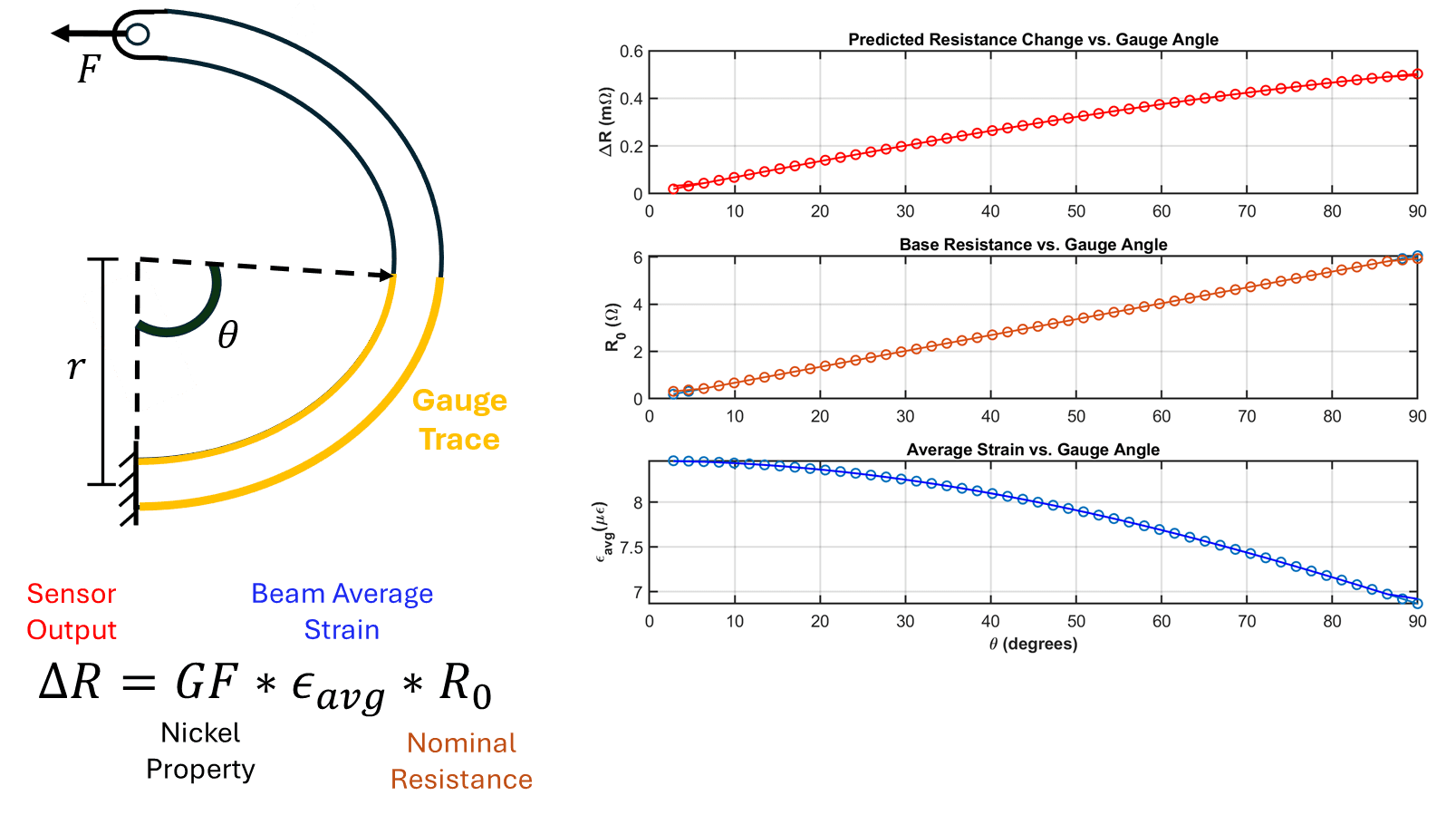

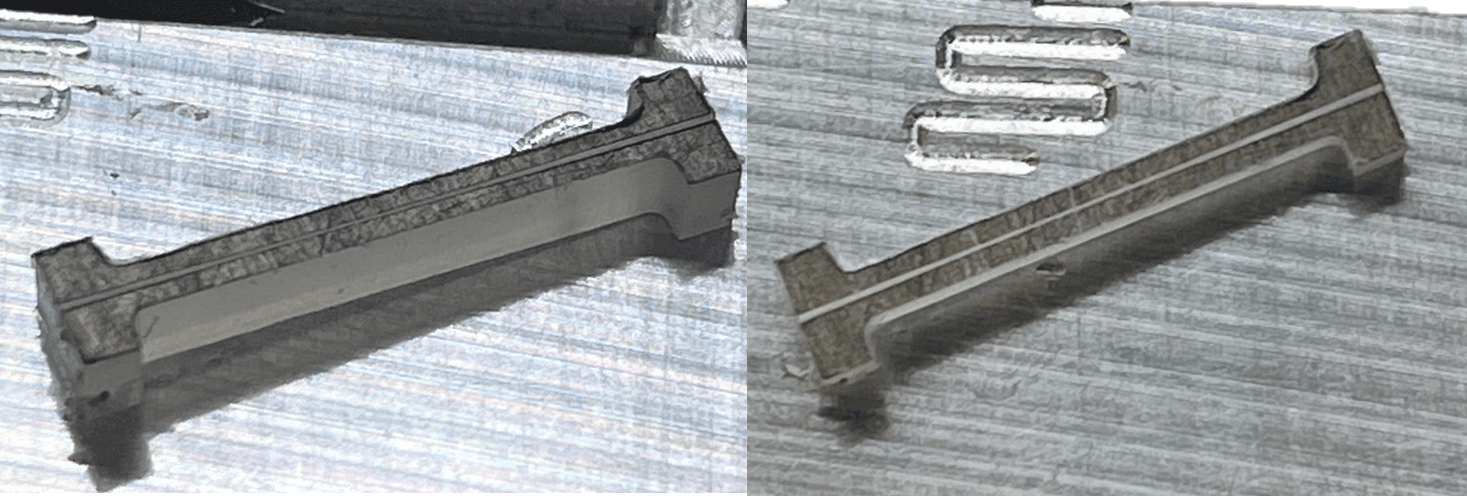

Strain gauges are machined on top of beams and still maintain max strain

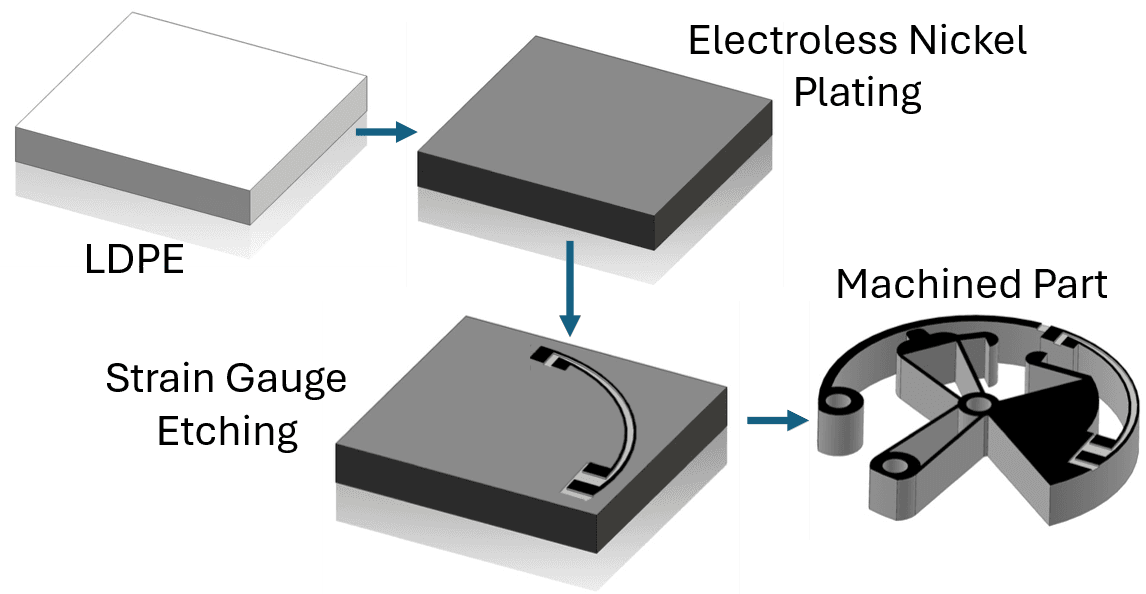

Process for machining of electroplated strain gauge

Gauges are designed to optimize resistance

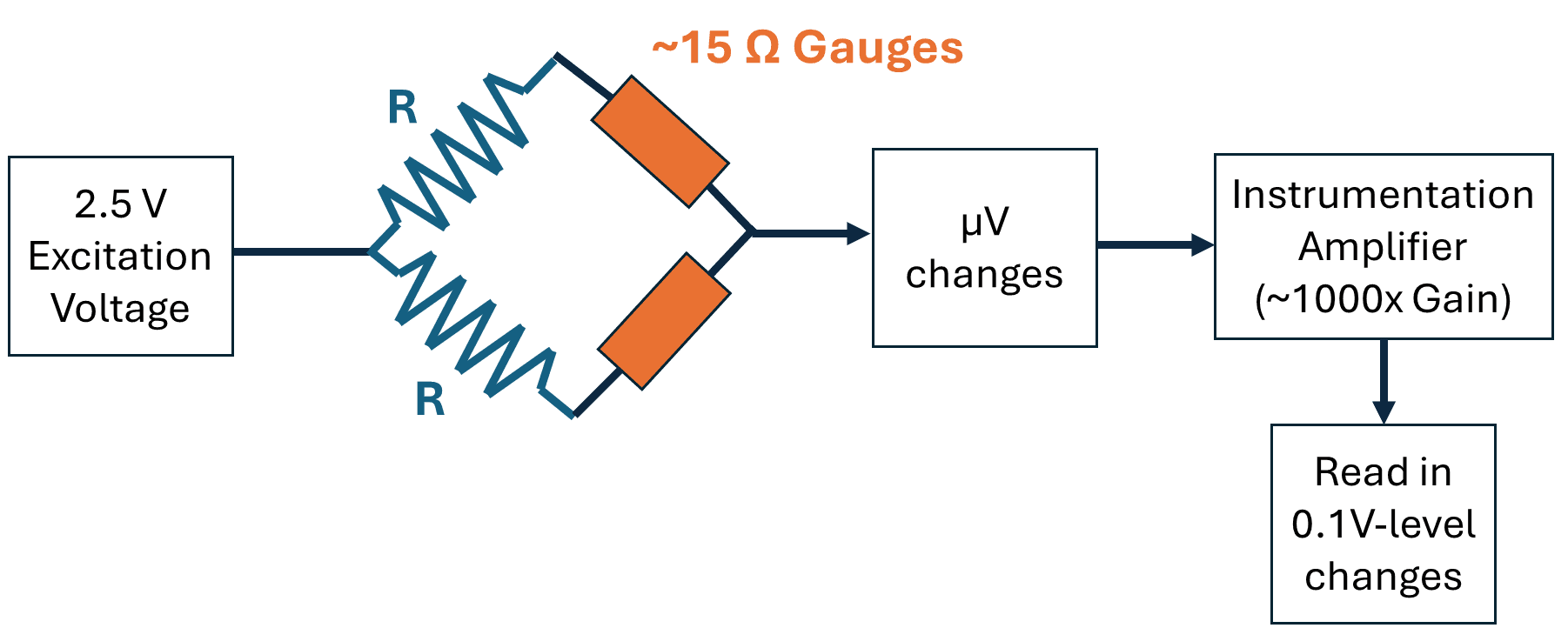

Wheatstone bridge circuit cancels out nonlinear errors

Manufacturing

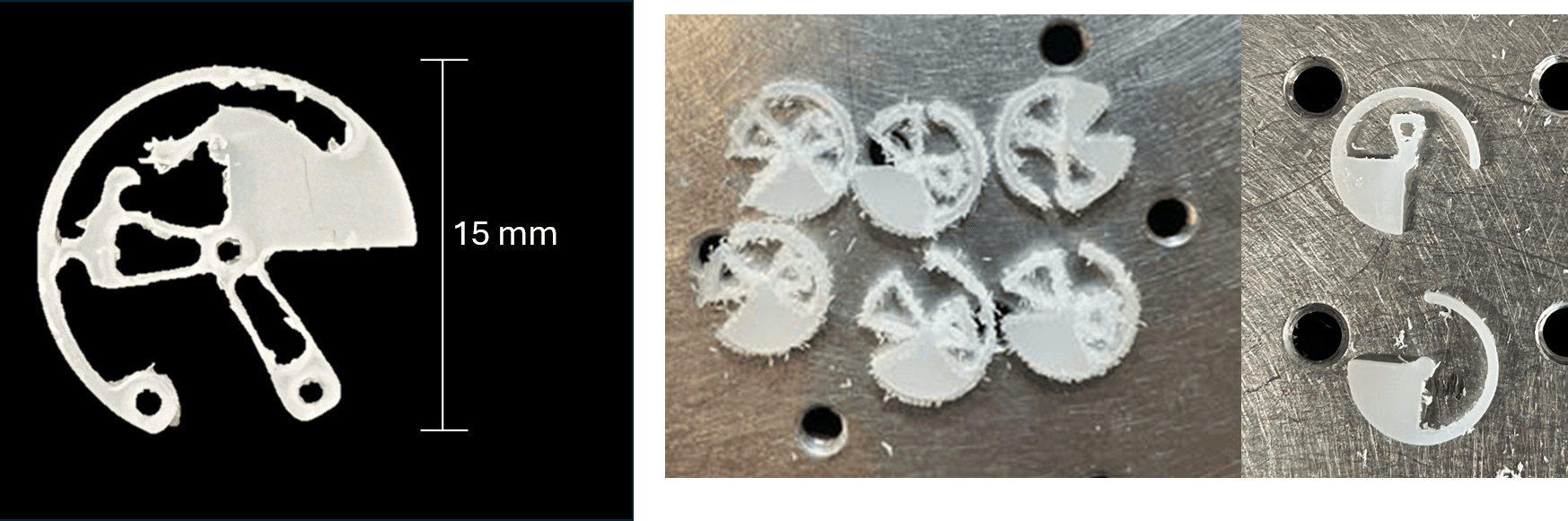

Flexures are micro-milled on a CNC machine with a custom vacuum chuck. Conventional cutting improved finish.

Preliminary Results

Successful latching & variable stiffness

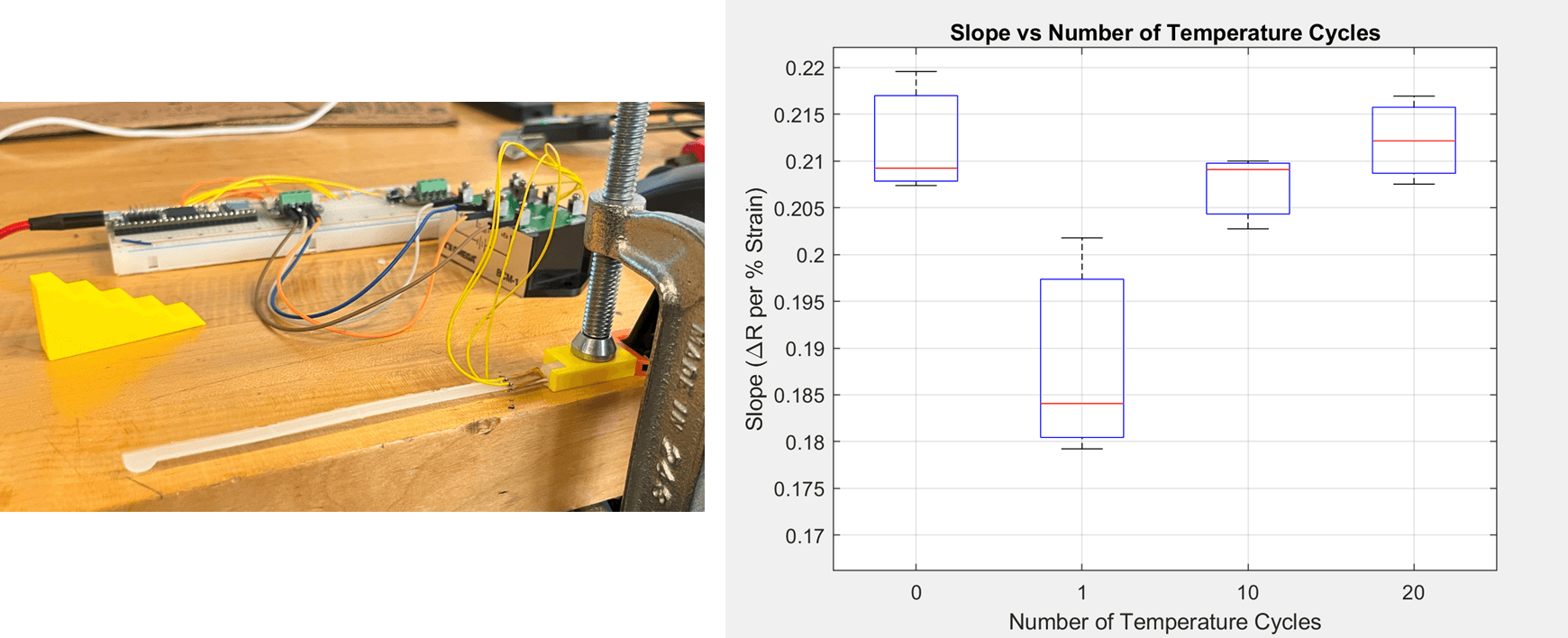

LDPE flexures resolve thermal creep errors after thermal cycling

User compatibility & muscle motion achieved

Plated gauges lack continuity

I am now actively exploring other methods for adhering custom sensors directly to plastic parts.